Robot solutions

Andon Robotics has developed external axes in the form of customer specific robot carriers and positioners that have since been configured to be functioning robotic systems for more than 30 years. Our focus had traditionally been on robotic welding, but we subsequently learned to handle material in an increasingly more efficient way in respect of both low and high volume series.

Our guiding principle in terms of robotic welding has always been: “You only earn money as long as the welding arc is alight”. This has resulted in us producing robotic solutions where downtime has been reduced to a minimum.

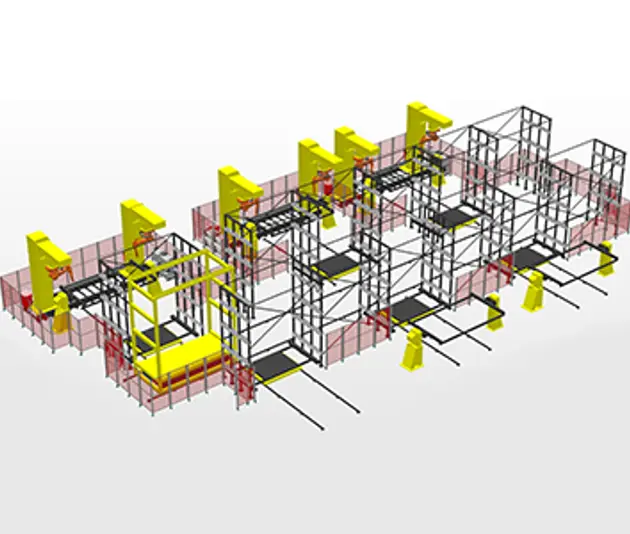

High automation cells

There is a clear trend to move away from conventional robot cells towards solutions that have a higher level of automation. Above all, loading and unloading are elements that can be automated through the introduction of handling robots. A handling robot can pick and drop material in fixtures. These are solutions that are particularly suitable for use in high volume operations.

Flexible cells

In customer based manufacturing, production batches can be quite small, which means that many product changes have to be done in the robot cell. Fixture changes take time – time the robot isn’t producing. In order to avoid getting into this situation, we have developed a dedicated pallet-based system (fixture material carriers), which ensure minimum robot downtime, markedly increasing efficiency in instances where many product changes are required.

Large and heavy

Andon Robotics is a spin-off from ABB, where we occupied a global role as a “Centre of Excellence” in the field of robot welding. Our foundation is ABB’s leading position on the market in terms of the development of robot carriers and positioners for large and heavy products. It ensures that Andon Robotics continues to develop its concept and can now offer qualified, customer-specific solutions within robot welding for both large and heavy products.